- By Arjit Garg

- Fri, 25 Apr 2025 01:34 PM (IST)

- Source:JND

The global electric vehicle (EV) market has witnessed remarkable growth in recent years. Valued at USD 500.48 billion in 2023, it is projected to expand to USD 1,891.08 billion by 2032, with a compound annual growth rate (CAGR) of 13.8%. This surge is driven by the urgent need for sustainable alternatives to conventional internal combustion engine (ICE) vehicles, which are among the leading contributors to air pollution worldwide.

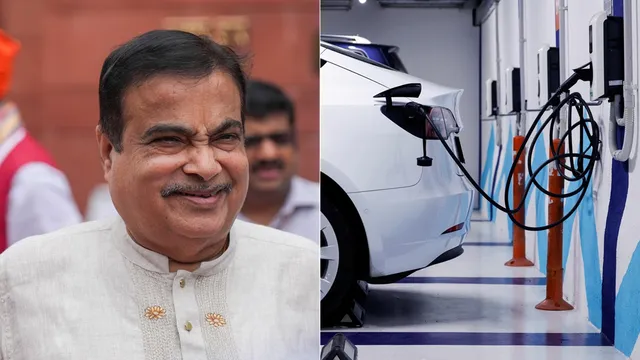

Governments across the globe have responded with policies that limit carbon emissions and promote cleaner energy adoption. Despite this global momentum, India faces significant challenges in making EVs the preferred mode of transport. To address this, the government has introduced the PM Electric Drive Revolution in Innovative Vehicle Enhancement (PM E-DRIVE) Scheme, a ₹10,900 crore ($1.29 billion) initiative spanning two years.

Building on the foundation laid by the FAME Scheme, which had allocated ₹3,679 crore ($438 million) for EV adoption, PM E-DRIVE focuses on accelerating the deployment of two-wheelers, three-wheelers, and public transport vehicles.

Also read: EV Maker Leapmotor To Make India Debut Under Stellantis Brand

This initiative aims to create an enabling ecosystem with upfront purchase incentives, expanded charging infrastructure, and a push for local manufacturing. If implemented effectively, it has the potential to reshape India's EV landscape, making clean and sustainable mobility a reality for millions.

A key aspect of the scheme is the phased manufacturing program (PMP) and financial support for EV manufacturers sourcing components locally. Unlike previous initiatives, this program does not impose a strict domestic value addition requirement, providing flexibility for companies to increase local sourcing gradually.

This presents a crucial opportunity to reduce dependence on imports, particularly for critical components such as batteries and semiconductors, while also fostering job creation and positioning India as a global manufacturing hub.

Equally important is the scheme’s emphasis on charging infrastructure. It allocates ₹2,000 crore to develop a nationwide network of public charging stations, including 22,100 fast chargers for four-wheelers, 1,800 for electric buses, and 48,400 for two- and three-wheelers.

This investment directly addresses consumer concerns about ‘range anxiety’ and is expected to drive adoption in Tier-2 and Tier-3 cities, bridging the urban-rural divide. While government incentives and policy measures play a crucial role in EV adoption, they alone cannot drive mass-scale transition. The industry faces fundamental challenges in supply chain resilience and financial structuring that must be addressed.

Supply Chain Bottlenecks

India has limited reserves of essential minerals such as lithium, cobalt, and nickel—key materials for battery production. As a result, domestic manufacturers heavily depend on imports, particularly from China. This reliance increases costs and exposes the sector to geopolitical risks and supply chain disruptions.

As highlighted in the Economic Survey 2025-26, India's dependence on Chinese imports for these critical minerals remains a major vulnerability in achieving self-sufficiency in EV production. A targeted strategy to develop local battery recycling facilities and alternative battery chemistries could help mitigate this issue.

Financial Structuring Hurdles

The cost of financing remains a significant barrier for EV manufacturers and consumers. High-interest rates on loans for EVs, combined with a lack of structured financing options for fleet operators and ride-hailing services, slow down adoption.

Unlike traditional ICE vehicles, which have established resale markets and financing structures, the EV sector is still evolving in this regard. Introducing specialized financial products such as lower-interest loans, residual value guarantees, and leasing incentives could help overcome these barriers.

One of the most pressing concerns is the restrictive nature of the Production-Linked Incentive (PLI) scheme. While designed to promote domestic manufacturing, it primarily benefits well-established industry players, making it difficult for startups and small enterprises to participate. This limits competition, slows innovation, and ultimately restricts consumer choice.

For a competitive and innovative EV ecosystem, the government should introduce a graded second phase of the PLI scheme (PLI 2.0) tailored to startups and smaller manufacturers. Special incentives or dedicated funding for companies focused on breakthrough technologies—such as next-generation battery systems, vehicle-to-grid (V2G) integration, and lightweight EV components—would accelerate innovation and help level the playing field.

At present, the opposite scenario exists, the stringent eligibility criteria for the PLI scheme disproportionately favor established automakers that already benefit from economies of scale. Addressing this gap is crucial to fostering a dynamic and diverse EV market that serves the needs of Indian consumers across different segments.

The PM E-DRIVE Scheme provides a much-needed policy framework for sustainable mobility in India. However, its success hinges on addressing key structural challenges—strengthening domestic supply chains, easing financial barriers, and creating an inclusive ecosystem that nurtures startups and smaller players.

A collaborative approach involving industry leaders, policymakers, and financial institutions is essential to overcoming these hurdles. With the right investments, partnerships, and policy interventions, India is well-positioned to lead the global electric mobility revolution and achieve its ambitious EV30@30 goal—where 30% of new vehicle sales are electric by 2030.

Disclaimer: This article is authored by Mohal Lalbhai, Founder & Group CEO, Matter Motor. All views are personal.