- By Soumyaroop Mukherjee

- Mon, 06 Oct 2025 12:57 PM (IST)

- Source:JND

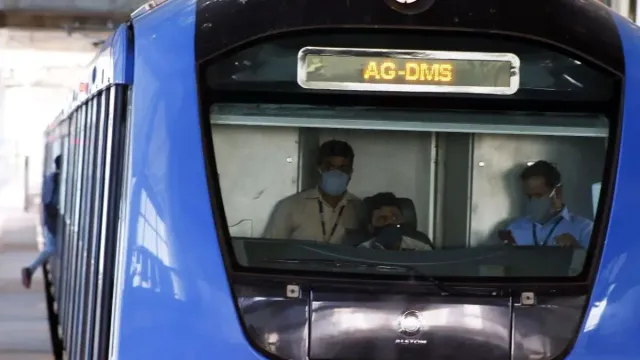

Phase II Metro: The Chennai Metro Rail (CMRL) is set to commence work for one of the most challenging stretches of the Phase II project, between Thiruvanmiyur and Indira Nagar, in November. Two twin boring machines (TBM) have been deployed in this regard to create a 650 metre path between both points, the officials were quoted as saying by the Hindu.

The stretch is part of Corridor 3. Corridor 3 from Madhavaram to SIPCOT via Adyar (45.8 km) is a part of the 118.9 km stretch of the Phase II project and has a huge stretch of 26.8 km of underground network.

The CMRL officials said that excavation works at the Thiruvanmiyur site have been progressing smoothly for the past few weeks. While one of the TBMs has been lowered, the other one will be put into action soon to escalate the work.

The major challenge for the officials is to chalk out a path through the hard rock. Metro officials further said that they are currently excavating at a depth of 22 metres at Thiruvanmiyur. Owing to the presence of the hard rocks, the tunnelling work is expected to progress very slowly in the 650-metre stretch. Usually, the ideal time for creating twin tunnels for such a short distance is a matter of a few months. But in this case, the construction of the twin tunnel may take up to a year, according to the officials.

“We did expect to encounter hard rock at Thiruvanmiyu, but didn’t foresee that it would be such high-quality hard rock like granite. Initially, the contractor planned to carry out controlled blasting to break them and complete the excavation. But as a better alternative, the contractor chose to use chemicals and disintegrate the hard rock,” an official was quoted by the Hindu.

The CMRL officials also feared that if the machines are used constantly to accelerate the process of drilling, the cutter head discs of the TBMs can wear out faster. In this case, the parts will have to be changed repeatedly, a process called ‘cutterhead intervention’, which may prolong the process of excavation.

“Cutterhead intervention may have to be done several times for both machines along this stretch and could be time-consuming,” the official added.